|

|

|

|

New

Improved Magic Bean Bag

- Step By Step Instructions -

|

|

Left: My original medium bean

bag

- 8 lbs.

Right: slightly larger Magic Bean

Bag - 6 lbs. 3 oz. |

Why

is this called the Magic Bean Bag? Read on and you'll

find out when you get to the end.

When

I decided to make another basic bean bag based on Scott

Fairburn's double bag design, I wanted to improve

upon my previous medium sized bean bag, namely, to make

it lighter in some way. I also wanted to use a better

fabric that was waterproof, and to include zippers so

I could empty it easily for travel. This time I decided

to document the process, since Scott's instructions leave

much to be desired for clarity and detail. For this new

bean bag I'm using some rugged and waterproof 600 denier

Cordura fabric in the popular Realtree Max-4 HD pattern,

which I luckily found on the Rockywoods.com

web site. At last check they did not have the Max-4 any

longer, but they carry their "True Timber Flooded Timber"

pattern, which is a fair substitute for Max-4. Of course,

they have other camo patterns and solid colors too. The

bean bag doesn't have to be camo, but I've used this fabric

for other projects, and I like that it will match my other

gear.

|

| Materials

needed |

|

|

| Flooded

Timber pattern |

Realtree

Max-4 HD pattern |

Lets's get started:

Unlike

my earlier bean bags, I've chosen to put a zipper in this

one, mostly because I already have a suitable zipper on

hand. It took a bit of thought to figure out how to install

a zipper with this design because the obvious method for

installing a zipper on this bean bag was, in fact, nigh

onto impossible because of the back-to-back design. I

also came up with a hopefully easier means of filling

both sides of this "double bean bag" design using only

one zippered opening. The only materials needed are your

choice of fabric, and a zipper.

STEP A ONE: Cut two

pieces of fabric, each 8.5 inches by 28 inches (each

one makes a bag). Using 8"x26" will work quite

well too. You can alter the bag size by using different

dimensions from mine. Note that the camo pattern on

my fabric is printed on one side only, so the other side

is blank. Thus it has an obvious front and back side.

The zipper I'm using is a 7-inch metal zipper. A zipper

longer than 7 inches is unnecessary. It can be a vinyl

zipper, but I thought maybe metal would be stronger.

|

|

Bean

filler slot &

rectangular stitch box |

Zipper

cut-out pattern |

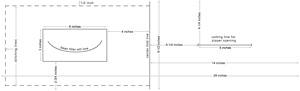

Refer to

this layout

measurements

diagram |

STEP

A TWO: Mark the stitching lines, zipper location,

and a slot opening for filling beans in the second bag

as shown in the photos at right. All these marks are done

on ONE piece of the fabric. Measure the 28-inch length

and mark a center line where the fabric piece will fold

in half later. The zipper slot line is drawn centered

on the left side of the fold. It is 5 inches long with

a 3/8 to 1/2-inch long "stop" line centered on each end.

This zipper slot will be cut later, but NOT now.

Next, on the right side of the fold, find the center point

of that half and mark a 6" x 3" rectangle in

the center. This rectangular box is the stitching line

for joining the two bean bags back-to-back. Inside this

rectangle draw a curved line as shown in the photo. This

line will be slit later so the beans can fill the

second bag from the first bag via the zipper. Also on

this half, draw a stitching line 1/2-inch in from the

three edges only (but not along the fold line). These

three edges will be stitched together to form each bag,

while the fold will make the 4th edge, requiring no stitches

there. (refer

to the layout measurements diagram for detailed measurements)

STEP A THREE: On the second piece of fabric, mark

a center line for the fold, just like on the first piece.

Also mark the stitching lines on one half of this second

piece, 1/2-inch in from three sides just as on the first

piece. No other marking is needed on this second piece

of fabric.

------------------------------------ Now

it's time to do a little sewing. -----------------------------------

First, install the zipper... But why zipper first?

The

normal procedure is to stitch these bags together "wrong

side out", leaving a gap through which you then turn

it right side out. You would then pour the beans into

these gaps and stitch them shut on each bag. But if you'd

rather have a zipper close the gap, sewing a zipper into

this opening would require accessing the back side of

the fabric, which is now INSIDE the bag. Oops, won't

work.

|

|

|

| Sewing

hem in zipper slot |

Hemmed

zipper slot edges |

Zipper

flap hemmed edges |

But

there is a solution..... put the zipper on the side of

one bag before sewing the bag shut on itself. With the

zipper pre-installed, you can sew the bag all the way

shut with no open gap, then turn it right side out through

the zipper opening. This places the zipper away from the

seam around the bag where it could potentially scratch

your lens, or your vehicle.

Here's how to do it -

STEP

B ONE: Locate the 5-inch long mark you made for the

zipper slot. Snip along the full length of this line and

across the "stop marks" at each end to create a slit.

Then fold under each side of the slit and sew a hem to

make a neat edge that won't unravel, as in this

photo. The finished hem on the zipper slot should

look like this

photo.

|

|

| Unzip

zipper about 1 inch |

Zipper

grip aligns like this |

STEP B TWO: Before sewing in the zipper, we'll

first make a flap to cover the zipper. Cut out a small

piece of fabric 2-1/4 inches by 8-1/2 inches, and fold

over about 3/16 inch along all four edges. Sew this hem

to make a neat edge all the way around like the upside

down sample

in the photo. This will become the cover flap.

STEP B THREE: Now, unzip the zipper about one inch

as shown in this

photo and center it under the zipper slot so that

the zipper ends extend about one inch beyond each end

of the slot cut-out. With the piece flipped over you can

see how the partially opened zipper

pull tab is now at one end of the slot. The slot is

intentionally shorter than the zipper in order to help

insure beans won't fall out if the zipper isn't quite

pulled all the way shut. Now pin the zipper in place as

shown in both the photos.

|

Cloth

end tabs are

stitched close together |

Zipper pull tab can slide into

the end "pocket" to prevent

bean spills and scratches |

Tail end of zipper is also sewn

across to seal zipper slot |

Although

this particular zipper top is designed to spread apart,

in this application the zipper top will never be spread

apart. The cloth end tabs should be sewn into place to

prevent that. This photo shows how the open end cloth

tabs

are sewn close together (bottom view) and sewn

across (top view), while this photo shows the

opposite end sewn across to prevent bean leakage at

that end as well.

STEP B FOUR: Double stitch each side of the zipper

into place along the edges of the zipper slot. On the

end where the teeth are spread apart, pull

the tabs close together before stitching in place.

Stitch

across the other end of the zipper as well.

| |

|

|

| |

Velcro

is added to the flap and below

the zipper, then the flap is sewn on |

The

finished zipper flap protects

against possible scratches |

STEP B FIVE: Now for the flap over the zipper to

guarantee no scratches. Sew some hook and loop Velcro

strips below the zipper and onto the 2-1/4 inch by 8-1/2

inch zipper flap you made earlier. Then sew the flap to

the upper edge of the zipper slot, being careful not to

sew into any of the metal pieces of the zipper (you wouldn't

want to damage your needle). The velcro

and completed flap are shown in these photos at far

right.

Joining the two bean bags -

|

| Two

pieces aligned face to face |

That seems like a lot of explaining

just to put in a zipper, but please be patient with me.

I am endeavouring to be thorough. Okay, it's time to join

these two bean bags (or maybe I should say join the two

pieces of fabric that will become the bean bags).

STEP

C ONE: Place the two pieces of fabric together,

one on top of the other, FACE TO FACE, or front to front

(if you prefer that terminology) and align the edges.

As you can see in

the photo, the piece with the markings is on top so

the rectangle you drew is visible. This rectangle is where

you will be sewing next, stitching around the line forming

the box. But don't sew just yet. Go on to

the next step.

STEP

C TWO: Cut some strips of fabric 3/8 to 1/2-inch wide.

You will need a total of 36 inches (3 ft.) to go around

the rectangle on both sides of the fabric. See

the photo for a better idea how this will be used.

(You can cut these strips from scraps if you wish.

It can even be a different fabric as it will be on the

inside and not seen.) These strips will reinforce

the fabric along the stitches, so use fabric at least

as sturdy as the bean bag fabric. Now, set these strips

aside until we're ready for them.

|

|

|

|

|

How

the reinforcing strips

will be used later. |

Pin

the fabric together

inside the rectangle. |

Stick

a pin through at each

corner mark of the rectangle |

Mark

a dot on the back where

the pin comes through |

Connect

the four dots to correctly align the rectangle on

the back |

STEP C THREE: With the two bean bag pieces face

to face, align the edges, then pin

the two pieces of fabric together inside the box.

This will keep them from shifting while sewing and handling.

STEP C FOUR: Transfer the rectangle lines to the

back piece of fabric so you can see where the reinforcing

strips go on the back side. --- Here's How: Stick

a pin through both pieces in one corner of the box.

Flip over the piece and mark

a dot next to the pin where it pokes through to mark

the corner position on the back piece. Do this with each

corner. Then all you need to do is play "connect

the dots" with the corner marks, and you'll have the

rectangle on the back piece correctly positioned.

|

Tape

strips around

rectangle and stitch |

Remove

tape and stitch

Remove

tape and stitch

twice more around strips |

Stitch

around curved slot,

Stitch

around curved slot,

then cut through slot |

STEP C FIVE: Get the reinforcing strips you cut,

and place them around the rectangle, centering them on

the lines. Using painter's tape (or masking tape will

do), tack down the outside corners so the strips will

remain in place. Do this to the rectangle on each side.

Then carefully (so you don't knock the strips or

tape off) stitch around where the rectangle lines would

be under the strips. This does not have to be exact. Just

follow the center line of the strips. Then remove all

the pins, and remove the tape. Now you can stitch around

again about 1/8-inch outside the first stitch,

and once more about 1/8-inch inside the first stitch.

That will give you three rounds of stitching for thorough

reinforcement.

STEP C SIX: Now stitch all the way around the curved

line (the bean filler slot) in the middle of the rectangle

as in this

photo. Then snip through the fabric along the curved

line to open a slot. This is a pass-through allowing you

to pour beans into the second bean bag. The slot is curved

because it allows opening wider than a straight cut.

| |

|

|

| |

Flap

is positioned and

sewn on three sides |

Flap

helps prevent migration of beans from one bag to

the other |

STEP

C SEVEN: The last thing to do here is to cut a piece

of fabric 6" x 3". I cut mine from a green scrap of Cordura

left from another project. This piece is positioned over

the curved slot, offset about 1/2-inch from one long side

of the rectangle to give more overhang over the curved

slot. The flap is then sewn around two short edges and

one long edge (do NOT sew all four edges). This will act

as a cover flap for the slot, helping to keep migration

of beans between bags to a minimum, while still allowing

you to fill beans through the slot. Since this flap is

on the inside, and not visible, there is no need for hemming

the edges..... unless your fabric is prone to fraying

on the edges. The Cordura fabric I am using does not fray

easily, so I didn't hem the edge.

Believe it or not, you're almost done -

Now

all that is left to do is actually sew the edges of the

two bean bags. This is where the magic happens.

| |

|

|

|

| |

Fold

the fabric piece with the zipper into a bundle and

pin with safety pins |

Another

view of the bundle

pinned with safety pins |

Be

sure you can reach through

the bean filler slot and access

the safety pins for later removal |

STEP D ONE: Take the fabric piece with the zipper

and fold it onto itself into a small bundle. Pin the bundle

together with safety pins. Photo

#1 and photo

#2 both show views of how this looks when done. This

is necessary to keep this half of the project out of your

way while you sew the first bean bag.

Be

sure this bundle does not get caught in the seams when

sewing the edges of the first bean bag. Furthermore,

I HIGHLY recommend using medium to large safety pins

for this. DO NOT use sewing pins. WHY? Because you will

need to reach into the sewn bag and pull out this bundle,

and sewing pins will STICK YOU and HURT. Safety pins are

much safer, and they will hold the bundle much better

than sewing pins.

Before

the next step, take time to reach

through the bean filler slot and insure you can access

the safety pins for later removal. If you pin the bundle

too tightly, you might have trouble reaching in later

to undo the safety pins and pull the bundle out.

STEP D TWO: Now fold the remaining fabric piece

over onto itself, covering up the bundle as in this

photo. Then align each edge and pin all around the

edges so they will not shift. Now you are ready to sew

around the three edges, stitching directly over

the outline you drew in STEP A THREE. DO NOT sew along

the folded edge. It is completely unnecessary. Once you've

stitched once around all three edges, remove the pins

and stitch around two more times between the first stitch

and the outer edge. These extra lines of stitching are

for safety, in case a stitch comes loose. You won't have

to worry about beans leaking out or about having to repair

the stitching. The photos below will step through these

instructions.

|

|

|

|

| Fold

the fabric piece over the bundle and align all the

edges |

Pin

the fabric together

around the three edges. |

This

shows the opposite

side after pinning |

Here

the three rows of stitching

are done, ready to reveal the

magic bag inside |

Are you ready for some magic?

| |

|

|

|

| |

Pull

fabric and remove safety

pins through the bean filler slot |

With

your pins removed, fish

out the rest of the fabric |

Voila,

the first completed

bean bag magically appears |

STEP E ONE: Reach into the bean filler slot and

fish around for the safety pins. You can probably pull

some fabric out to gain access to the pins. PATIENTLY

pull and tug and wiggle until you can get the safety pins

out. Now it will be easier to pull

all the insides out through the bean filler hole.

Again, be patient, tugging here and tugging there, and

soon all of it will work out through the slot....... and

VOILA,

you now magically have one completed bean bag, and

the zipper side you had bundled up is out for you to begin

sewing it into the second bean bag.

See, I told you it was magic.

STEP E TWO: UNZIP THE

ZIPPER NOW. Repeat, UNZIP

THE ZIPPER NOW. After you have UNZIPPED

THE ZIPPER (it should be open now and NOT

SHUT ), you just need to basically repeat Steps D

One and D Two. Fold up the completed

bean bag into a small bundle and pin it with safety

pins so it won't get caught in the stitching when you

sew around the second bag. Next,

fold over the fabric piece with the zipper so you

see the back of the zipper, and so the bundled bag is

covered up. Align the edges and pin

around the edges as before. Now, be sure the ZIPPER

IS OPEN. It has to be open so you can later pull out the

other magic bean bag. It could prove difficult to unzip

the zipper from the wrong side when you can't get to the

pull tab.

| |

|

|

|

|

| |

Fold

the first bean bag into

a bundle and safety pin |

Fold

zipper side

over bundle |

Pin

three sides

for stitching |

Stitch

all three sides

and remove pins |

STEP E THREE: With the edges now aligned and pinned,

you are ready to sew

around the three sides as before. After stitching

around once, remove the pins and then stitch twice more

around for safety. When you finish stitching, simply reach

into the zipper opening (you DID have the zipper open,

didn't you?) and begin

pullling out the first bean bag that is bundled up

with safety pins. With the safety

pins removed and the full insides pulled out.....

| |

|

|

|

|

| |

Pull

up the pinned bag

and remove safety pins |

Patiently

pull the remainder

of the bag through the

zipper opening |

Abbra

Cadabbra... two

completed bean bags

attached together |

Fill

both bags via

one zippered opening |

Abbra Cadabbra..... you now have two

fully seamed bean bags attached together.

Unlike

my other bean bags, this one is much more easily filled.

Using a single

zippered opening to fill both bags eliminates hand

stitching altogether. It also allows me to fill and empty

the bag very easily, in the event I need to travel with

lighter weight.

| |

|

|

| |

8

lbs. of dried beans looked

like about the correct volume |

Substitue

filler of 1/2"

cubes of dense foam |

Getting the Magic Bean Bag ready to use -

|

4

lbs. of pinto beans filled

one side only this far, correlating

to both sides requiring

over

9 lbs. of beans |

How

much does this double bean bag hold? I started out with

two

4-pound bags of dried pinto beans, and poured one

full bag (4 lbs.) into one side of the bean bag. It was

about

80% full. That was just a little bit slack for my

taste, though it may suit some folks just right. I'm estimating

it will actually hold 4-1/2 pounds per side, tops. I'm

pretty sure you cannot cram 5 pounds into one side. If

you could, it would be too stiff to form well to the lens

or a car door. So my estimate to completely fill both

sides will be 9 to 9.5 pounds of pinto beans (4.5 to 4.75

lbs. per side). If your bag dimensions are different from

mine, then you will need to adjust your expected amount

of filler.

I

specify "pinto beans" because that's what I used. If you

were to use some other filler... as in larger beans, or

smaller beans, peas, buckwheat, etc., ..... they will

have more or less air space between each "bean" and therefore

will alter the amount of that kind of bean needed, as

well as the total weight. Just be aware that different

filler materials will come out with a different weight-to-volume

ratio.

| |

|

|

|

| |

The

Magic Bean Bag

ready to use |

The

finished Magic Bean

Bag with no filler |

It

folds up into

a small package |

This

"weight-to-volume ratio" can be altered by using

other filler material as well. I tried an experiment here,

hoping to cut down on the weight, while still filling

the bags. I have some odd "foam" that is sort of slick

and plastic-like, and it's much firmer (compresses only

about half as much, or less) than the dense gray foam

I use for equipment padding. It's no good for padding,

though it is used to make form-fitted molded spacers for

products like TVs and heavy weight items in boxes. I diced

up some of this stuff into little

1/2-inch cubes and mixed it in with the beans to take

up space without adding weight. I wanted to see if I could

reduce the weight while still maintaining a good conformity

to my lenses, car door, etc.

My

mixture (by volume, not by weight) is about 1/3 diced

foam and 2/3 beans. Instead of requiring about 9 pounds

of beans, it worked out to only 6 pounds of beans, plus

the 3 ounces of foam pieces and fabric. This filled my Magic

Bean Bag just right. It feels like it's all beans, and

conforms the same as before, but weighs at least three

pounds less than using all beans. I'm extremely pleased

with the results. |

| |

|

|

|

|

|